The Tesla Cybertruck’s 48-Volt Architecture Is No Revolution

[ad_1]

Tesla’s pickup ditched the 12-volt battery to much fanfare, but there’s reason to be skeptical.

Jan 18, 2024 at 9:43am ET

The automotive industry latched on to 12-volt electrical systems in the Fifties and hasn’t changed since. Even hybrids and EVs with high-voltage traction batteries still have a 12-volt battery to run things like window regulators, seat motors, headlights, and more. While we’ve seen several 48-volt “mild-hybrid” vehicles over the years, Tesla is the first to go 48-volt on a pure EV with the Cybertruck, and its marketing team wants you to know about it.

“The entire supply chain, the entire design infrastructure is designed for 12 volts,” Musk said in an interview. “This is why it’s been stuck at this absurdly low number for a long time.” It’s something he feels passionate about, so much so that Tesla sent a manual on how to build a 48-volt car to the CEOs of major automakers, something Ford head Jim Farley confirmed on Twitter.

It seems like another instance of Tesla breaking new ground, forcing legacy companies to play catch up. Think over-the-air software updates, or more recently, Gigacasting. The Cybertruck’s switch to 48-volt electrics is being pitched as the same, but as always with Tesla, there’s truth to parse from its hyperbolic messaging.

First off, why is upping voltage a good idea? Ohm’s Law tells us that voltage is equal to current times resistance (V=IR). Assuming a fixed resistance, raising voltage lowers current. Lowering current means you can use smaller wires to transmit the same amount of power. This saves weight, money, and improves vehicle efficiency. Higher current also corresponds to more energy lost as heat. A 12-volt system is therefore not only inefficient at higher power levels but requires components to have larger heat sinks than higher-voltage systems.

Automakers shifted from 6- to 12-volt electrics in the 1950s to address growing power needs posed by more advanced electrical components, especially ignition systems for higher-compression engines. Since then, the industry has generally stuck with 12-volt electrics, even as the number of electrical systems within cars has grown tremendously.

The 48-volt electrical architecture of the Audi Q8.

The auto industry worked to move to a higher voltage standard in the 1990s and early 2000s, anticipating the need for higher electric power in passenger cars. A 1999 SAE paper written by Ford engineers about a 36-volt system concluded that “[n]ew electrical functions features with power requirements of several hundred watts or more will require the availability of a high-voltage power supply in order to be practical in term efficiency, cost of wiring, packaging, and semiconductor controls.”

But a large switchover never happened.

“[Automakers] were able to find efficiencies elsewhere that eliminated the need to spend that extra money to go to a higher-voltage system,” said Sam Abuelsamid, principal research analyst with Guidehouse Insights.

Now, however, we do have some 48-volt cars on the market.

“As we got into the late 2000s,” Abuelsamid said, “we started adding so many features to cars. Heated seats, heated steering wheels, adaptive dampers, all these things that consume electrical power. Plus, wanting to electrify other electric components on the engine to reduce parasitic losses.”

This drove some automakers to adopt 48-volt systems, but Abuelsamid explains that all use at least two DC-DC converters to run 12- and 5-volt electrical components. While an automaker may need 48 volts for, say, an integrated starter-generator or an active anti-roll bar, there isn’t a good enough reason to spend big money to replace or redesign electrical components that don’t have a large power draw. Going to 48 volts may enable smaller wiring, but there’s a practical limit to how small your wire can be in the first place. Plus, 48-volt systems require stronger connectors and shielding to reduce the chance of arcing. Forty-eight volts is also about the upper limit for an electrical system that doesn’t require more stringent safety standards.

While it’s hard to know exactly what is and isn’t 48-volt on the Cybertruck—Tesla dissolved its PR department years ago, so we have few channels to ask them—we know that some components are lower-voltage. Pete Bannon, Tesla’s head of low-voltage electronics, said in an interview that the audio amplifiers for the Cybertruck are 24 volts, and the car has provisions so it can also be jump-started by a 12-volt battery if the 48-volt battery dies.

A perusal through the online parts catalog for the Cybertruck shows that some 48-volt components must have been designed specifically for the truck. The part names for both window regulators note that the components are 48 volts. However, the part number for the truck’s radar-sensor assembly is very similar to that of the Model Y, which could mean it’s a 12- or 5-volt component.

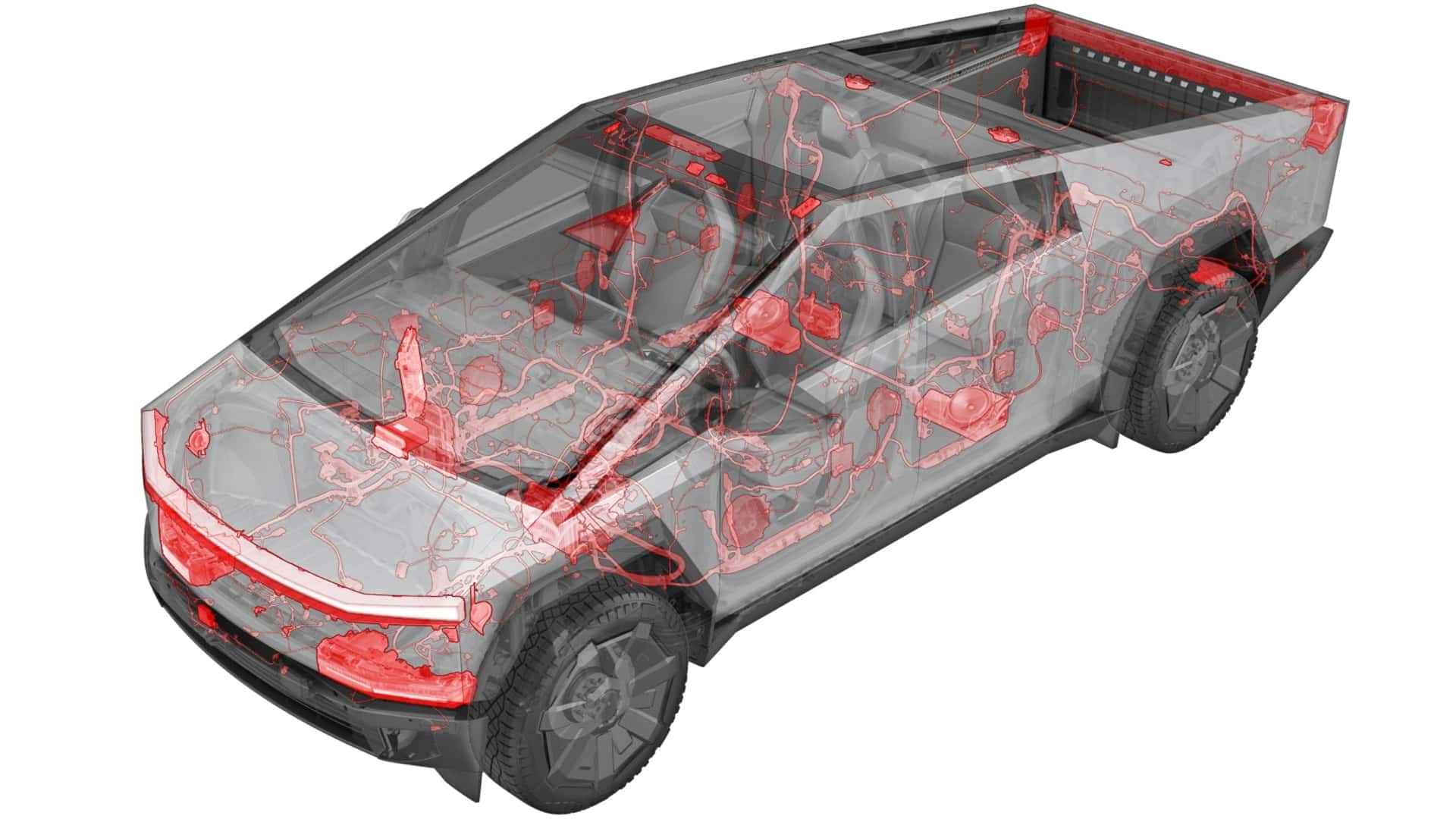

So, what Tesla is doing here doesn’t appear to be radically different than what other automakers have already done. Tesla engineers and Musk claim they’ve reduced the weight of the wiring harness, and the number of wires crossing the car, but that’s also thanks to a new Etherloop data system.

The Tesla Cybertruck’s steer-by-wire system.

The Cybertruck’s 48-volt system also enables the use of steer-by-wire (SBW), the first of its kind in a production car that does not have a traditional steering shaft. (The Infiniti Q50 offers SBW, but it has a traditional column in place as a backup.) Abuelsamid suspects that Tesla isn’t doing this for the Cybertruck because it’s using components from a supplier that’s developed a SBW system for 48-volt vehicles. In some videos featuring various Cybertruck components, you can see a ZF logo on the Cybertruck’s steering rack. Presumably, Tesla is using components designed and built by ZF that can work in both EVs and internal-combustion cars.

But beyond SBW, Abuelsamid wonders what’s the point of going 48-volt in an EV. When stepping from 12 to 48 volts in an internal-combustion car, you can jump from around 2/2.5 to 10/12 kW of electricity available for various electrical systems—a huge gain. “For an EV, that’s not an issue,” because much higher voltage is readily available. “An EV is already running at typically 400 volts and up, and all of your power is coming from the battery. Even for a low-end EV you’re looking at a minimum of 100 kW that you’ve got in there, and generally much more. Again, there’s not really a good driving force to go to 48-volt for that.”

Perhaps, then, Tesla isn’t playing four-dimensional chess. It’s not to say 48-volt systems are without benefit—maybe it was the only way Tesla could actualize steer-by-wire. But beyond that, it’s hard to see how different what Tesla is doing than other automakers that use 48-volt systems, and the benefits in an EV are even less clear.

The system sums up the Cybertruck story. Is it a work of revolutionary genius or too clever by half?

[ad_2]

Source link